My post from TheSamba...

Ok, so with my bus' dash apart for some paint work, and a new windshield I decided to take on my wiper's for PM. I think it went really well, but there are a few small issues that I came across so hopefully you guys can help me out!

The rack was already out of my bus from last weekend. So getting started was easy

I wiped off the dust bunnies and massive chunks of grease that had made a home under the dash and quickly found the C clips. From my recent undertaking of the slider, I had really thought these C clips would be a nightmare to get off. But I used two small screwdrivers and they slid off much easier than I anticipated.

The shaft's were coated in caked on grease. So these went into a tub of degreaser while I moved on with the rest of the project

The drive lever came off simple, but it wasn't a 13mm as told. It was a 10. It looks to have been stock so maybe this is a difference between early/late bays. With the nut off, the lever was actually held in place with caked on grease. I used the flat edge of my screwdriver to gently help it up. I used care to make sure I didn't bend anything.

From there, I removed the three bolts that held the motor to the rack.

I remove the center nut, and gently loosened the perimeter screws, I say gently because I was trying to make sure the cover didn't fall off potentially tearing the paper gasket inside.

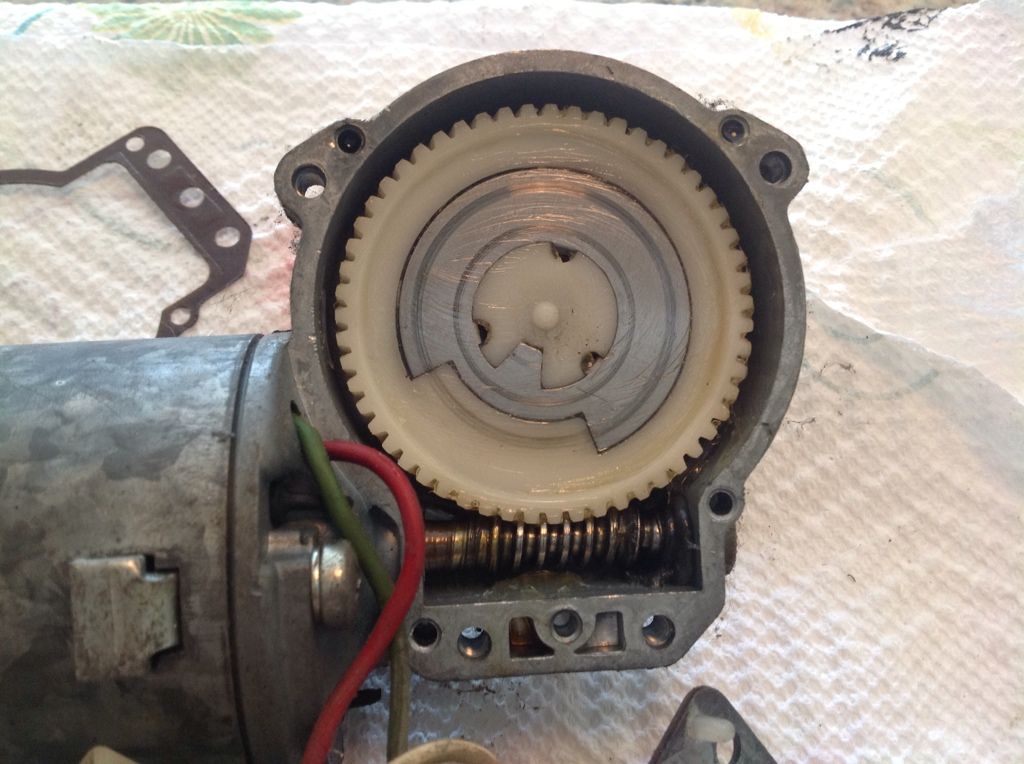

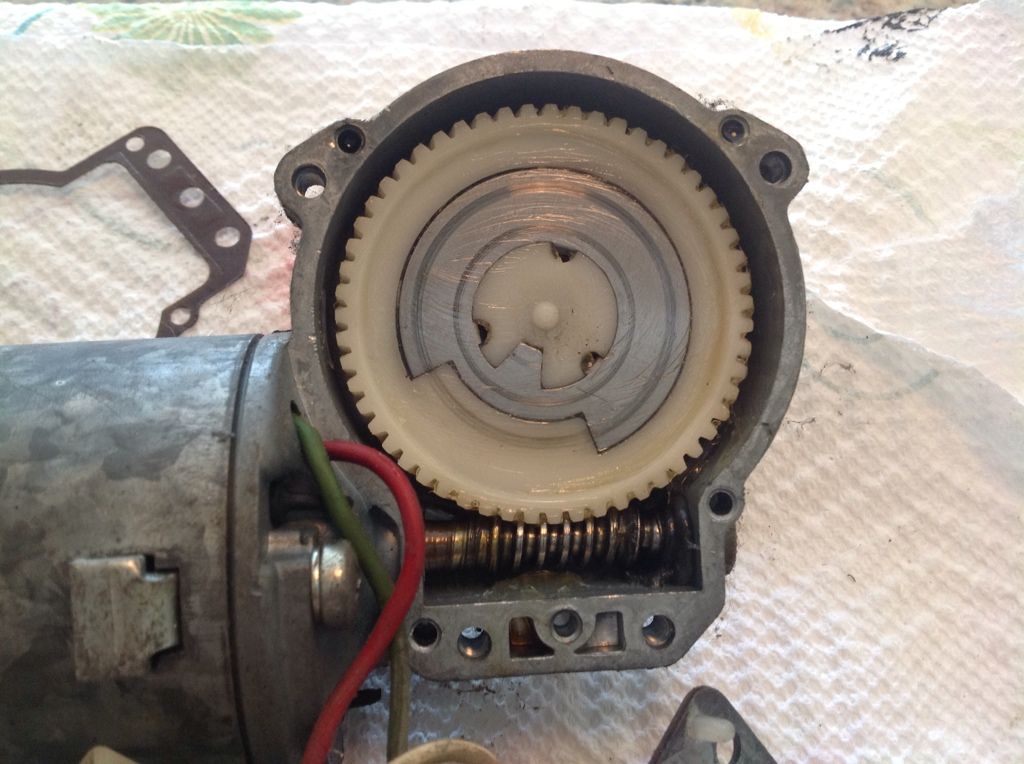

This is what I found inside.

I didn't know if the faint black tinge to the lubricant was ok, so I wiped it off and used some that had pooled in the underside of the plastic gear. This is the "record" and the copper fingers that Colin mentioned in the original write up.

Here it is with a new coat of grease.

I used the blade of my razor to gently clean off old grease from the copper fingers. Then I took a second to see exactly how the innards worked. I gently laid the paper gasket back in place, and put the cover back on over the gearbox. I use a piece of sandpaper to scuff up the ground and it'ts contact to the case. I replaced all the screws and moved on to the motor.

I didn't listen to the instructions, mostly because I

thought I understood what was going on. Needless to say I made more work for myself. But I removed the case from the motor. The magnet inside made the commutator pull from the gear. (Note, I ignorantly skipped the part where I replaced the drive lever to keep the gear, and subsequently armature from moving DON'T DO IT MY WAY!)

Here's the armature. (I think that's what this part is!)

The inside of the motor case, without the armature, check out those magnets!

It was at this point that I started to realize how things

really worked. I had always thought the motor worked one way, then reversed to make wipers move left, and right. Man! I was wrong! Its cool to see, the armature spins, and that turns the worm roller at the end that interlocks with the white plastic gear. that gear drives the arm on the back which spins. The two opposing arms move the shafts, which are connected to the wipers themselves. NIFTY!

Now, I will also mention that it was just at this point where the springs and brushes came out. I had read about this in the instructions, but didn't realize at what point to expect it.

I cleaned everything, oiled, and began to reassemble. It was a bit of a trick to get the springs and brushes back in place. But I tricked my mom into inserting the armature while I held the brushes.

Also, while you're here... I had noticed it was a bit tricky to get the armature to seat 'square' there is a bit of play while the roller seats properly with the gear.

I was hesitant and didn't understand what was happening so I wound up taking off the gearbox cover again to see... Thats when I realized why the armature wasnt sitting square at first. I gave it a gentle spin and it worked into place with the gear.

It took two tries to get the motor case back over the armature without moving the armature or dislodging the brushes again. I also found that there is a small "cone like" (shaped almost like the Apollo Capsule) insert that sits at the base of the armature, it seems to act as a centering key that has one rounded edge which mates in the nipple at the end of the motor case. I dropped this piece, thankfully I saw where it went on the floor and after looking around I made the best guess as to where it fit on the motor.

I lined the case screws and their tabs up, and locked it all down.

Then I cleaned all the parts

I'm missing some of the wavy washers. Where can I get a set and what size are they?

And, am I correct in my placement of the little "cone"?